QUICK MENU

PROCESS

Process Flow Diagram Welcome to MIRAE INDUSTRIES Co.,LTD Global marine equipment provider

- PROCESS

- Process Flow Diagram

- Process Flow Diagram

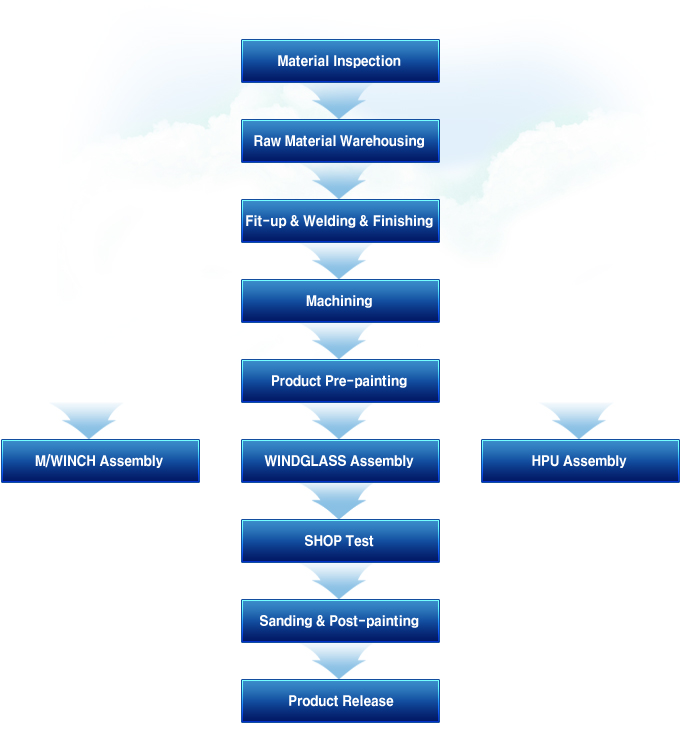

PROCESS FLOW DIAGRAM

Quality management for customer satisfaction with our customers only growing in the MIRAE Industres.

-

Process Flow

-

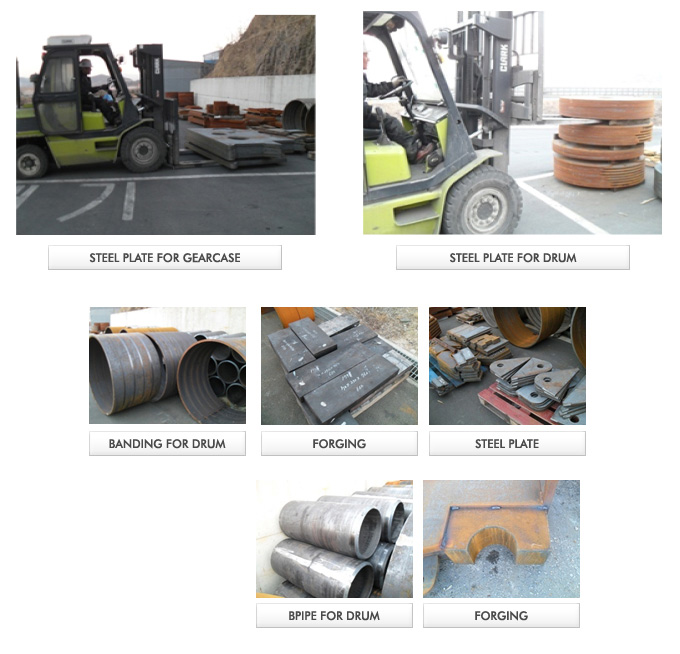

Raw material

- Explanation on the process

- When raw materials(steel plate, forging, pipe etc.) are ware housed, unload by classifying into each line using a forklift.

- Store unloaded raw materials after classifying them into the thing that is required for bolier making process and the other.

- Ransport stored materials to dach applicable process using a forklift when fitting-up is being implemented.

- Facilities & Equipments to be used

- Forklift

- Main dangerousness, harmfulness,

hazardous substance - Forklift and colosion

- Overturn or narrowness due to unsafe freight loading

- Narrowness due to discordance of hand signal method

- Non-designation of foreman when handling heavy material

- Safety & Improvement measures

- Attach a waming sign ‘speed limit s 20 km’ installation of taillight, headlight and alert sounds

- Use of proper forklift and advance inspection of weight

- Be sure to move after confirming foreman’s signal when hand signal is required

- Work with advance hand signal in respect of product that securing a clear view is unable among heavy materials(two-person team)

- Forklift-related safety education

-

Boiler Making

- Explanation on the process

- Plan the shape of each cut component by fitting-up after referring to the floorr plan.

- Cut steel plate using oxygen futter after marking a portion of steel plate materials and proceed with fitting-up process

- Conduct welding process for each single product that fitting-up is completed.

- Facilities & Equipments to be used

- Co2 welder

- Oxygen cutter

- Crane

- Cutter

- Hand grinder

- Main dangerousness, harmfulness,

hazardous substance - Fire and explosion due to of LPG, oxygen / oxygen cutter

- Narrowness and cut when using figh-speed cutter

- Ocular diseases due to failure of wearing protective goggle in th course of selding

- Damage to eyes due to noise / iron filling dust scattering in the course of grinding

- Health disturbance due to (harmfulness) welding groove

- collision, falling, narrowness in the course of crane work

- Safety & Improvement measures

- Check hose for irregularities during the process.

- safety education

- Check sutter protecrtor for irregularties / designate the phrase ‘warmning : inspection’

- Implement training to wear welding mask and protectibe goggle at all times.

- Wearling protective goggle and earplug is recommended.

- Istall dust scattering protective partition and ventilator within the work place

- Be sure to wear a dustproof mask and implement safety education on health distrurbance.

- Implement stretching on a periodic basis(musculoskeletal system disorder)

- Understanding of surrounding working cpmdotopms / periodic ispection

-

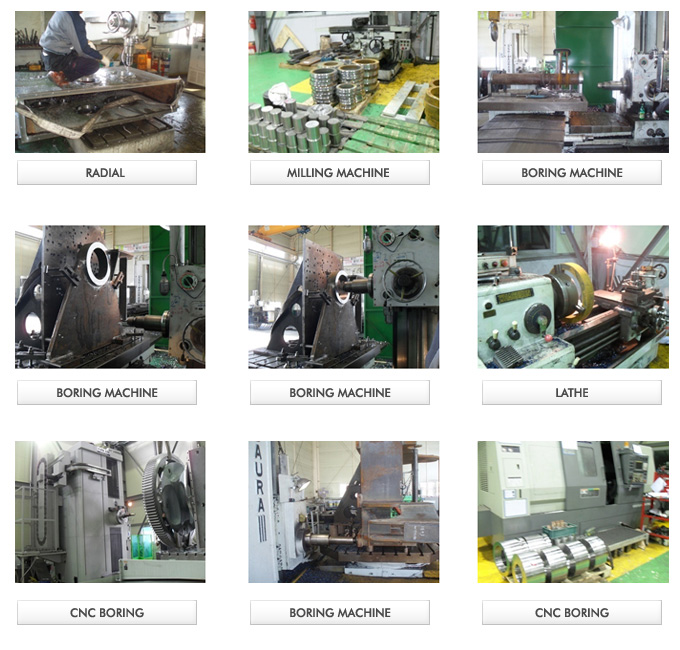

Machining

- Explanation on the process

- Work welded product by referring to the size specified on the floor plan.

Drilling / boring / radial work are the main methods of working - while operation is made based on the boring operation durring the primaty processing, floor plan size and tolerance processing / punching for radial work are impelmented in the secondary processing

- Upon completion of boring processing, ‘HOTE’ and ‘TAP’work are carried out on the punching location using a redial

- Conduct lathe milling process for the rest small - sized processed products.

- Facilities & Equipments to be used

- Lathe

- Tadial

- Milling machine

- Boring machine

- Crane

- Forklift

- Main dangerousness, harmfulness,

hazardous substance - Beting shoved by the rotating body of machine

- Backache when handling heavy material

- Narrowness due to faulty sling belt work

- Abrasion / cut due to chip dust scattering

- Health disturbance due to use of(toxic substance) cutting fluid / slide-way oil

- Colision, falling, narrowness in the course of crane work

- Safety & Improvement measures

- Pay special attention and implement inspection prior to operation of machine / use of leather gloves is recommended.

Implement stretching on a periodic bass(musculoskeletal system desorder) - Inspect state of tailpiece and use an exclusive clamp

- Istall chip dust scattering prevention facilly

- Wearing protective goggle and mask is recommended.

put up safety instruction and indicator board. - Understading of surrounding working conditions / periodc inspection

-

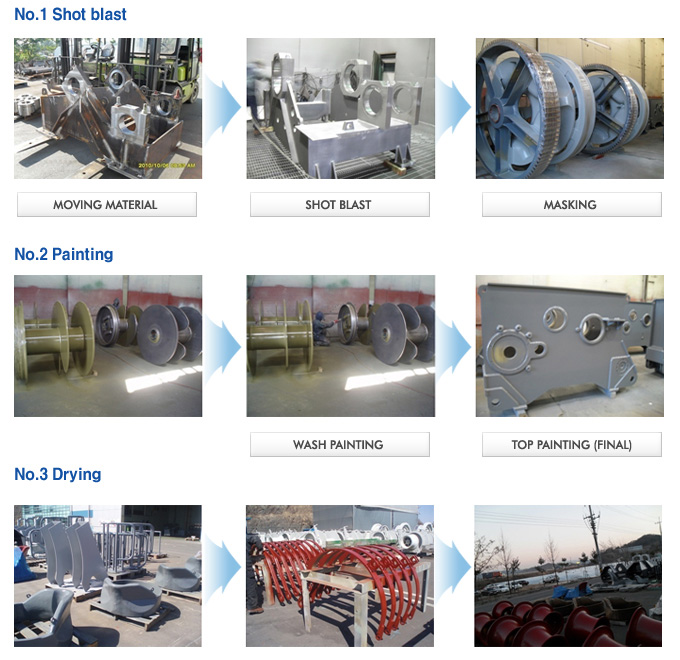

Pre-painting

- Explanation on the process

- Conduct shot blasting for processed product for removing rest and painting

- paint product that shor clasing is completead according to the painting specifications using painting equipment in order of wash painting / sealer / top painting

- Dry painted products

- Facilities & Equipments to be used

- Painting facility

- Crane

- Short gun

- Painting machine

- Spray gun

- Main dangerousness, harmfulness,

hazardous substance - Risk of fire due to work using paint and thinner

- Health disturbance due to use of (jazardous substance) paint / thinner

- Collision due to use of forklift

- collision, falling, narrowness in the course of crane work

- Safety & Improvement measures

- Remove the source of ignition and DO NOT USE inflammables within the workplace

- Wear a dustproof mask, canister mask and protectibe clothing.

- Attach MSDS(Material Safety Date Sheet) indicator board and implement education Inspect local ventilation system and replace filter on a periodic basis(bi-monthly)

- Refer to the forklift safety instruction

- Understanding of surrounding working conditions / periodic inspection

-

MW

- Explanation on the process

- After warehousing painted product into the plant using a forklift, review and arrange gear-case from the upper by referring to the floor plan of each line and assemble washed gear in each location in order of floor plan. After assmbling gear-case, assemble in order of drum clutch, stand, band and warping

- Facilities & Equipments to be used

- Tank for washing gear

- Sling belt

- chain vlock

- Air grinder

- Heating furnace(shrinkage fitting)

- Impect wrech

- Spanner /Hammer

- Hoist

- Main dangerousness, harmfulness,

hazardous substance - When used for cleaning gear oil tank fire

- (Hazardous materials). Health problems coused by the use of thinner

- Shrinkage fit caucaution when working with images

- Hand tools(hammer) caused by the use of a stenosis(finger)

- Grinding noise when working / metal powder eye damage by scattering

- Stocked for a long time due to reperirive work and nusculoskeletal

- Crane / forklift operations collision, fall or narrowing

- During welding thinner due to the use of fire

- Safety & Improvement measures

- Keep a fire ectinguisher around the tank

- Wear a dustproof mask

- Wear arm warmers and raduat gloves

- Remoce rest elements usibg a JIG

- Wearing protective goggle and earplug is recommended.

- Implement stretching ib a a periodic basis.(musculoskeletal system disorder)

- Understanding of surrounding working conditions / periodic inspection / forklift safety

- Implement education and point out mutually to prohibit inflammables in the course of welding process.

-

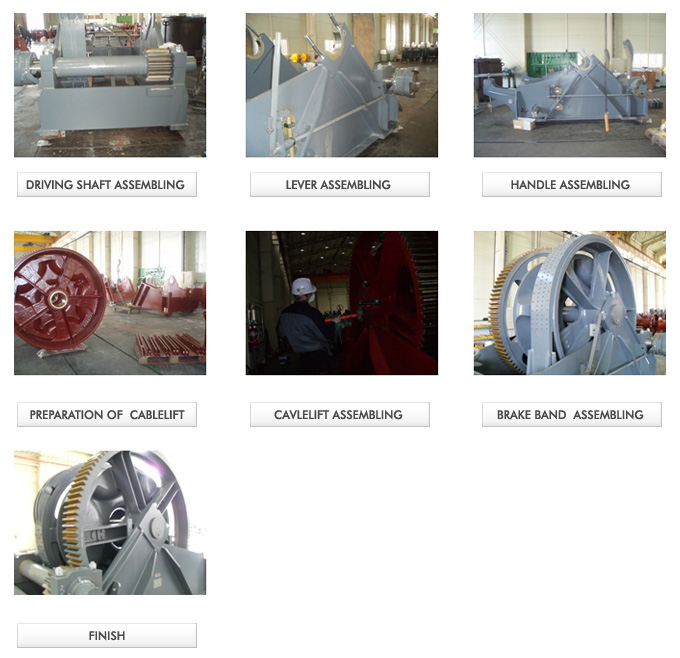

WL

- Explanation on the process

- After warehousing painted product into the plant using a forklift, arrange from the frame location by referring to the floor plan of each line and proceed in order of dricing shaft, calble lift and band lever handle as specfied in the floor plan

- Facilities & Equipments to be used

- Hammer

- impact wrench

- sling belt

- Spanner

- Chain block

- Hoist

- Air grinder

- Main dangerousness, harmfulness,

hazardous substance - Health disturbance due to use of(hazardous substance) thinner

- Stenosis(finger) due to use of hand tool(hammer)

- Damage to eues due to noise / iron filling dust scattering in the course of grinding

- Musculoskeletal system disorder due to stading and repetitive work for long hours

- Safety & Improvement measures

- Wear a dustproof mask

- Remove risk elements using a JIG

- Wearing protective goggle and earplug is recoomended.

- Implement stretching on a periodic basis. (musculoskeletal system disorder)

- Understading of surrounding working conditions / periodic inspection / forklift safety

- Implement education and point out mutually to prohibit imflammables in the course of welding process.

-

TEST

- Explanation on the process

- After self-test by conductiong a performance test on the assembled winch at the shop testing ground, implement owner inspecion and classification survey. tests shall be implemented in accordance with test procedure as follows

- Facilities & Equipments to be used

- Shop test facility

- Hoist

- impact wrench

- Jig for testing

- Sling belt

- Main dangerousness, harmfulness,

hazardous substance - Sliding tue to oil leakage on the floor of workplace

- Accident due to discordance between worker and signaler

- Damage due to damated wire in the couse of testing pricess

- Dermatitis due to use of(toxic substance)gear oil / hydraulic fluid

- Collision, falling, narrowness in the course of crane work

- Safety & Improvement measures

- Remove oil using thinner / fabric right after completion of work

- Be sure to moce after confirming foreman’s signal when hand signal is required.

- Maintain safety dispance using wure and attach a safety sign in the course of testing process

- Wearing rubber gloves is recommnended when sashing and oil work

- Understanding of surrounding working coudtions / periodic inspection

-

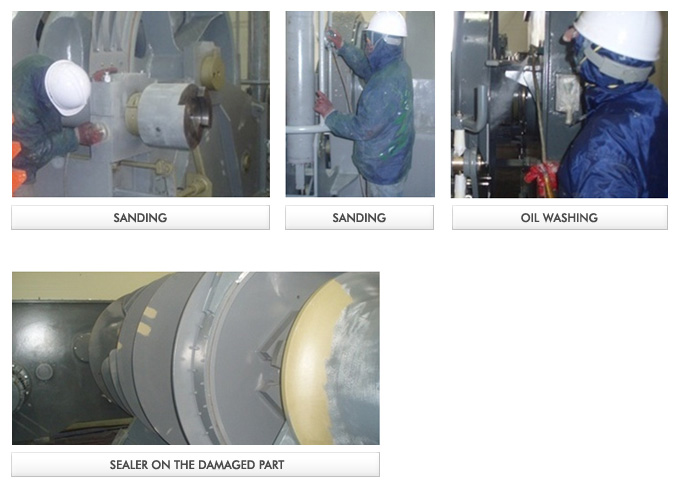

Post Paint

- Explanation on the process

- Upon completion of product inspecion, implement sanding process for failed painting and danaged part using a sanding machine and wash

- oil on the product and conduct top painting*final) using painting equipment

- Dry painted products

- Facilities & Equipments to be used

- Painting facility

- Crane

- Spray gun

- Painting machine

- Main dangerousness, harmfulness,

hazardous substance - Risk of fire due to work using paint and thinner

- Health disturbance due to use of (hazardous substance) paint / thinner

- Dollision due to use of forklift

- Collision, falling, narrowness in the course or crane work

- Safety & Improvement measures

- Remove the source of ignition and DO NOT USE inflammables within the work place.

- Wear a dustproof mask, canister mask and protective clothing, and attech MSDS(Material Safety Date Seet)

- indicator board and implement education.

- Inspect local ventillation system and implement education

- Inspect local ventilation system and replace filter on a periodic basis(bi-monthly)

- Refer to the forklift safety instruction

- Understanding of surrounding working conditions / periodic inspection

-

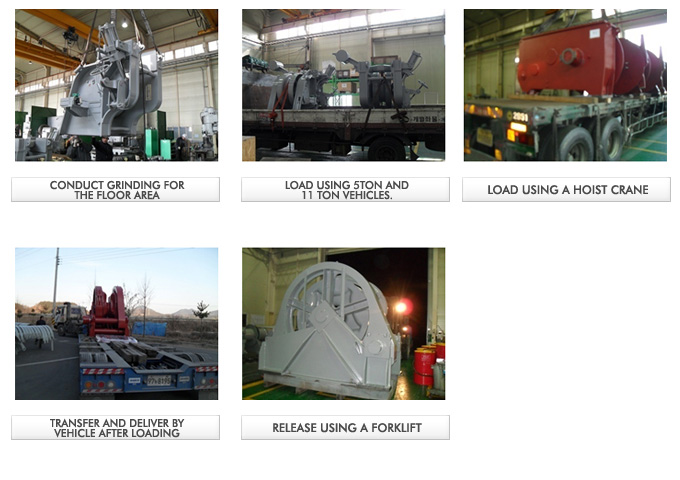

Release

- Explanation on the process

- Hang up completed m / winch and winlass on the crane and load on the vehicle using sling belt and chackle

- Load up completed product on the pallet on the vehhicle using a forklift and release by fixing product witha belt

- Facilities & Equipments to be used

- Forklift

- Crane(Hoist)

- Shackle / Sling belt

- Main dangerousness, harmfulness,

hazardous substance - Overturn when lifting optimal weight for forklift

- Collsion, falling, narrowness in the course of crane work

- Overturn of product due to use of abnormal sling belt

- Narrowness due to discordance of hand signal method

- Safety & Improvement measures

- Use of proper forklift and adbance inspecion of weight

- understanding of surrounding working conditions / periodinc inspection

- Inspection state of tailpiece and use an exclusive clamp.

- Work with advance hand signal in respect of product that securing a clear view is unable among heavy materials.(two- person team)

- Forklict-related safety education

:: Navigation ::

BUSINESS

PROCESS

MIRAE PR

:: Main Contents ::

- handling equipment manufacturers

- marine deck machinery

- marine hydraulic winch

- double anchor windlass

- positioning mooring winch

- electric capstan winches

- hyd winch

- hydraulic winches suppliers

- winch capstan

- windlass winches

- windlass anchor system

- marine cable lifter unit

- man ride winch

- tug boat rope reel

- roller type chain stopper

- MIRAE INDUSTRIES

Company: MIRAE Industries President: Jongsu Kang Registration No: 608-81-64957

Head offce / Factory: 269, Gongdanan-gil, Daechi-ri, Chilseo-myeon, Haman-gun, Gyeongsangnam-do, Republic of Korea

2nd Factory: 147, Gongdanan-gil, Daechi-ri, Chilseo-myeon, Haman-gun, Gyeongsangnam-do, Republic of Korea

3th Factory: 213-13, Wonseo-ro, Yongjeong-ri, Chirwon-eup, Haman-gun, Gyeongsangnam-do, Republic of Korea

TEL +82-55-587-8520 / FAX +82-55-587-8549 / Email sales-2@miraewinch.com

Head offce / Factory: 269, Gongdanan-gil, Daechi-ri, Chilseo-myeon, Haman-gun, Gyeongsangnam-do, Republic of Korea

2nd Factory: 147, Gongdanan-gil, Daechi-ri, Chilseo-myeon, Haman-gun, Gyeongsangnam-do, Republic of Korea

3th Factory: 213-13, Wonseo-ro, Yongjeong-ri, Chirwon-eup, Haman-gun, Gyeongsangnam-do, Republic of Korea

TEL +82-55-587-8520 / FAX +82-55-587-8549 / Email sales-2@miraewinch.com

Copyright(C) MIRAE INDUSTRIES CO.,LTD. All rights reserved. Designed By ITLIFE